Blog

Anthony Anti-Corrosion Coatings and Supplies BLOG

Getting stuck with your vehicle is never fun. Well, it is. Sometimes. We being children at heart and all that. After the recovery, life does not go on as usual. You now have salt particles stuck in the engine, on the chassis and all over the body. And this needs to be removed ASAP! This is also true for those occasion when you travel through rivers, play in the mud or chase the tides. Spraying down with water only is not enough. Applying a degreaser and giving it a good wash – not so much either. What is needed here is a thorough, deep rinse with a solution that will convert salt layers into water soluble particles . Wash with an anti-corrosion cleaner and rinse with clean water to remove all contaminants. Follow through with an oil treatment on the chassis and engine bay and a quick detailer on the body to bring back the luster and shine. Looking after you vehicle and using the correct products at the right time will keep your vehicle rust free and add many years to the longevity of the structure.

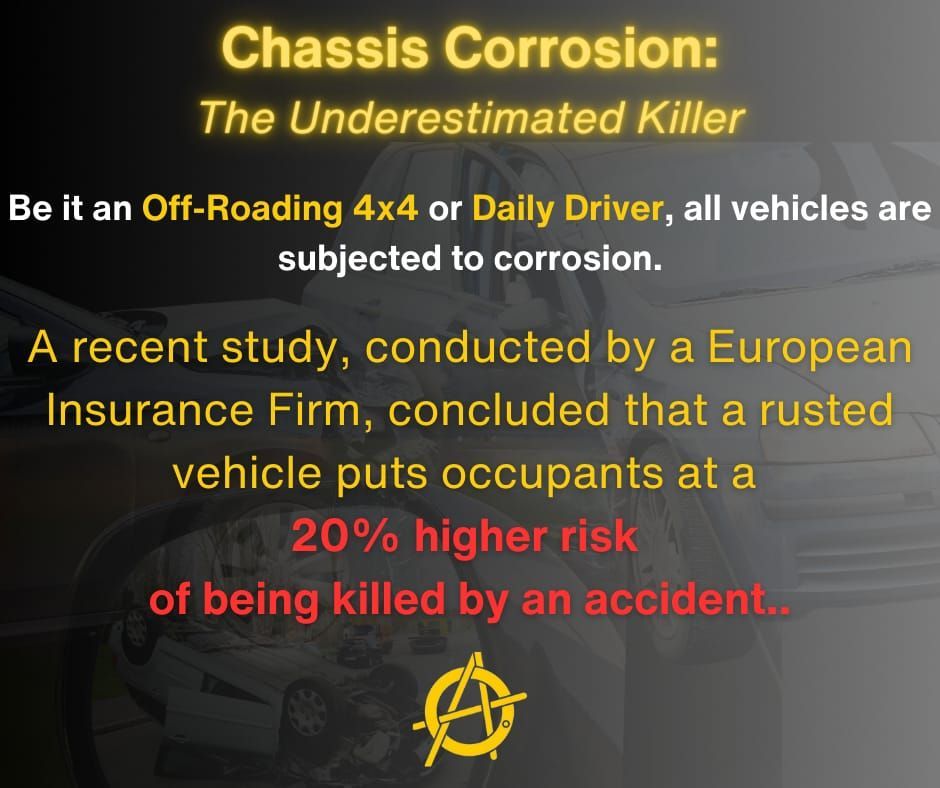

We all know and understand the importance of vehicle maintenance. In today’s economy, it almost goes without saying that prevention is better than cure, cure being replacing expensive parts and components due to corrosion damage. In the past, attention was placed mainly on body and engine maintenance. The chassis, being out of sight, seldom received love and attention, with potential dire consequences. Thankfully, this trend is rapidly changing. Let’s be honest. Your vehicle chassis carries the entire weight of your vehicle, passengers and goods being transported. When corrosion sets in, it compromises the integrity of the chassis, thereby placing you at risk by snapping or breaking and causing an accident or worse. Slapping on a coat of paint only hides the rust. This is not the ideal solution as rust continues to creep underneath the paint, slowly eating away at the substrate. It is therefore critical to choose the correct anti-corrosion treatment for your vehicle chassis. Let’s look at some options available on the market. Rust Converters Whilst these products are excellent for use in and around the house, as a chassis treatment it offers only temporary protection. Chassis rust needs to be completely removed with a chelating agent and / or sanding and mechanical removal. A rust converter will generally convert the top layer of rust, leaving the remaining rust to continue corroding the substrate. Bitumen and Rubberising Once again, fantastic products, when used as waterproofing. In our South African environment with hot summers, Bitumen softens in the heat, allowing contaminants to migrate to the substrate. When it cools down, it contracts again, trapping these contaminates, causing corrosion where the eye cannot see. A pin prick of damage in rubberising causes moisture to creep in between the coating and substrate, again causing corrosion that will only be discovered when it is too late. Removal of bitumen and rubberising is costly, time consuming and cannot be overcoated. Sandblasting is required to remove these products. Wax Coatings Wax Coatings are self-sealing, meaning that when damage occurs, it has the ability to repair itself. As it self-seals, it traps moisture and contaminants between the coating and substrate, resulting in rust creep. Additionally it never completely cures and will drip when the weather is hot. Powder Coating Powder Coating is unsuitable for vehicle chassis due to its inflexible nature. Easily damaged, it does not offer sufficient protection against rust creep. Powder Coating cannot be repaired and needs to be sandblasted and re-coated, making this an expensive and ineffective option. Aftermarket Paint Products When choosing the best paint, the following properties are crucial: Adhesion – strong adhesion ensures no flaking, peeling or rust creep Strength – chip and scrape resistance Flexibility – a vehicle chassis constantly flexes and bends, the coating must be able to move with the chassis Excellent anti-corrosion properties Acid, Salt and Alkaline resistant Thin Film even application – your mechanic will love you. No changes in nut and bolt sizes. Easy chip and chafing damage repair – choose a product with multiple over coating abilities that does not require the removal of the paint before reapplying. No paint is bullet proof. Off-roading vehicles will experience stone chips, scraping and sand blasting. Easy repair will save thousands in recoating. Oil Coatings Choose oil that penetrates , dries and has been tested against acid, salt and alkaline drag. Most oils on the market stay wet, dripping all over the place and needs to be reapplied frequently. Dust and grime settles in the wet oil, resulting in a dirty looking chassis. Before spending hard earned cash on products that only tick some of these requirements, contact us for solutions that have stood the test of time, and carry the “Anthony” stamp of approval. When all is said and done, proper chassis maintenance will add years to the longevity of your vehicle.